Platforms

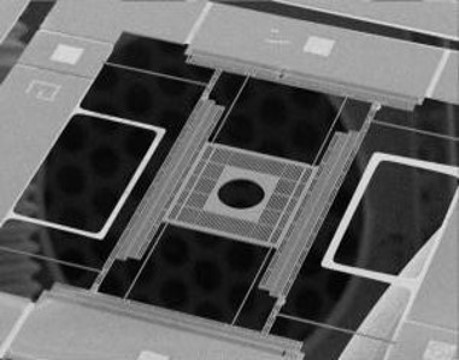

Design

Commercial and in-house developed software tools for glass and polymer flow calculations and pre-form fabrication; for the computational modelling and design of regular, doped and micro-structured (passive and active) fibres, for modelling modes and guiding properties (including bend losses), for calculation of performance and fabrication yield as a function of fabrication tolerances, for the assessment of elasto-optic and thermo-optic effects, probabilistic analysis tools for modelling of various physical phenomena (structural, thermal, electrical, electromagnetic and fluid).

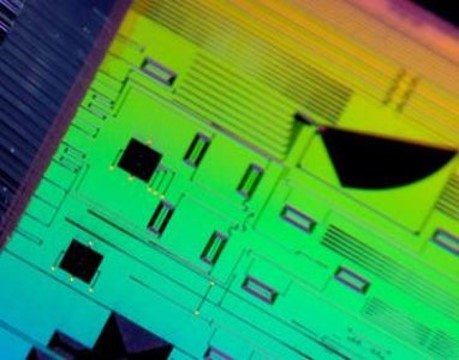

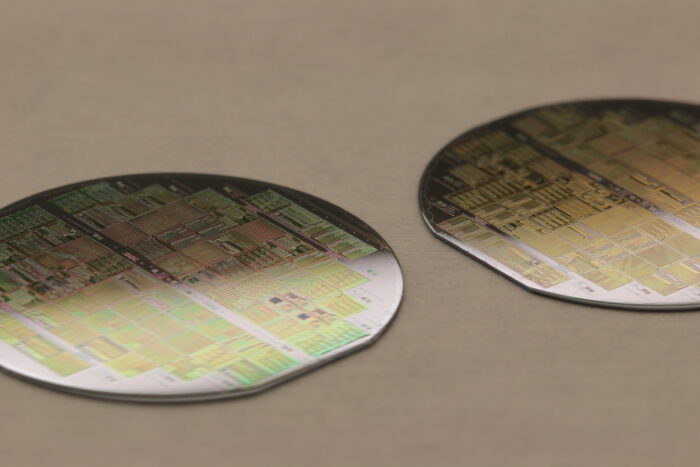

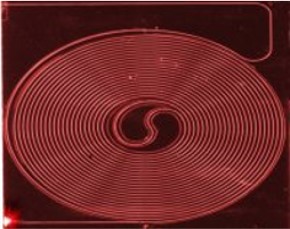

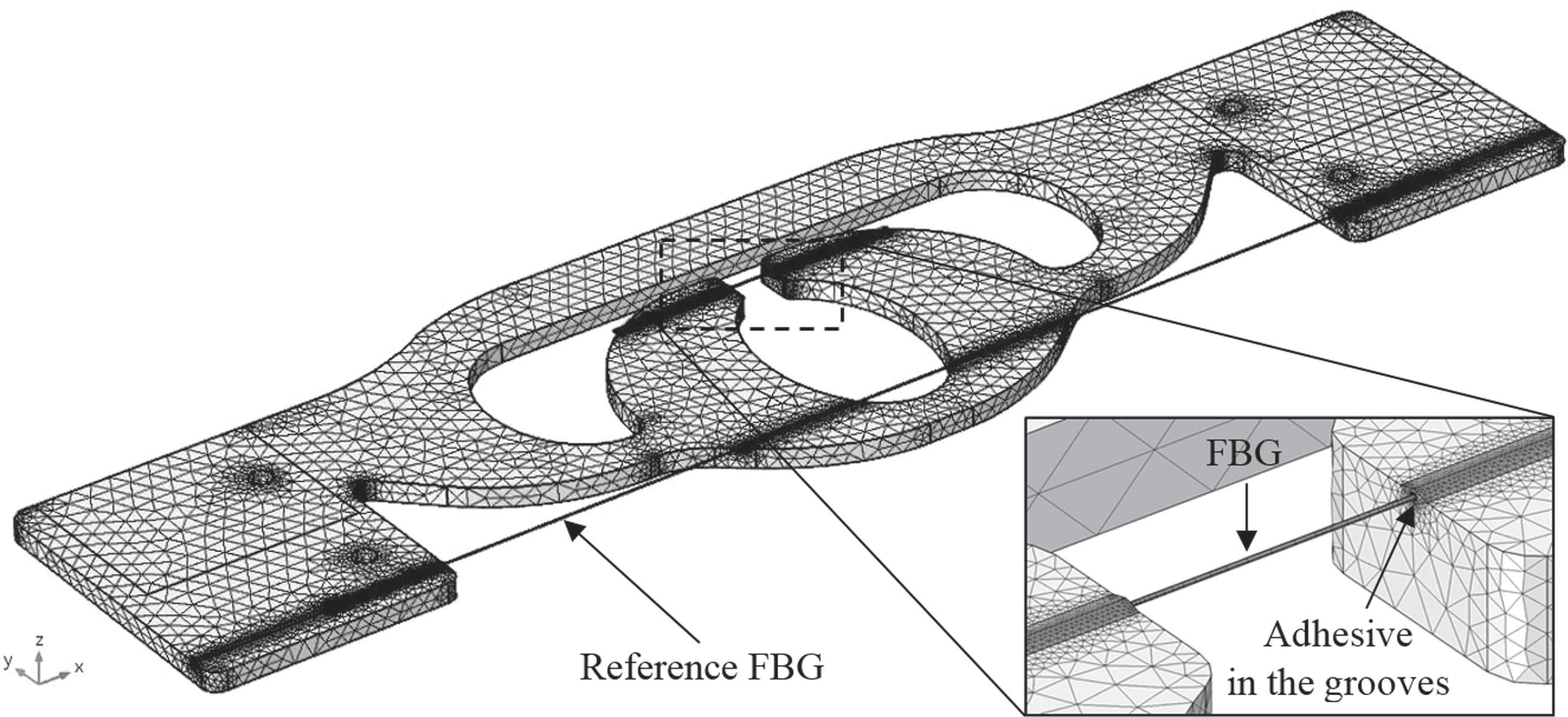

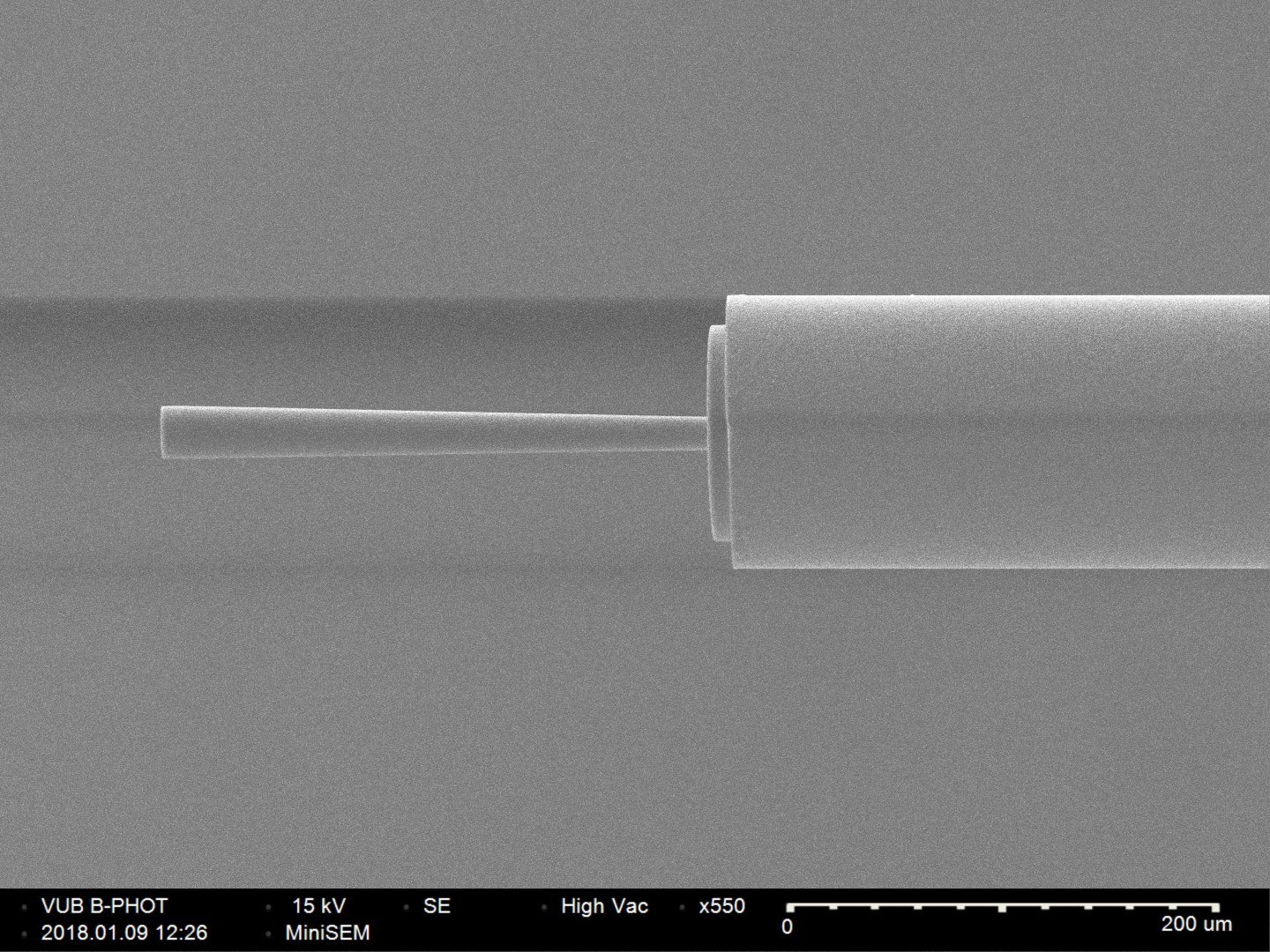

Prototyping

Furnaces for optical quality glass melting in small and large volumes, industrial grade MCVD and FCVD preform fabrication systems suitable for passive and active dopants, OVD preform fabrication systems suitable for large doped glass volumes, microtube and microrod draw towers, optical fibre drawing towers with industrial scale and extended manufacturing capabilities, single or dual coating application, preform spinning and preform pressure controllers, glass drilling/machining/forming, ultrasonic drilling, milling for double-cladding fibre, chemical preparation areas for doping of glass preforms, hydrofluoric etching system for etching of preforms and glass articles, wide variety of high intensity laser sources for laser processing and fibre Bragg grating manufacturing, various Bragg grating writing set-ups (Talbot, phase mask, point-by-point, …) including draw tower gratings, together with hydrogenation and thermal annealing facilities, specialty fibre splicing, termination and tapering equipment including filament based and CO2 laser based splicers, and for fluidic fibre infiltrations.

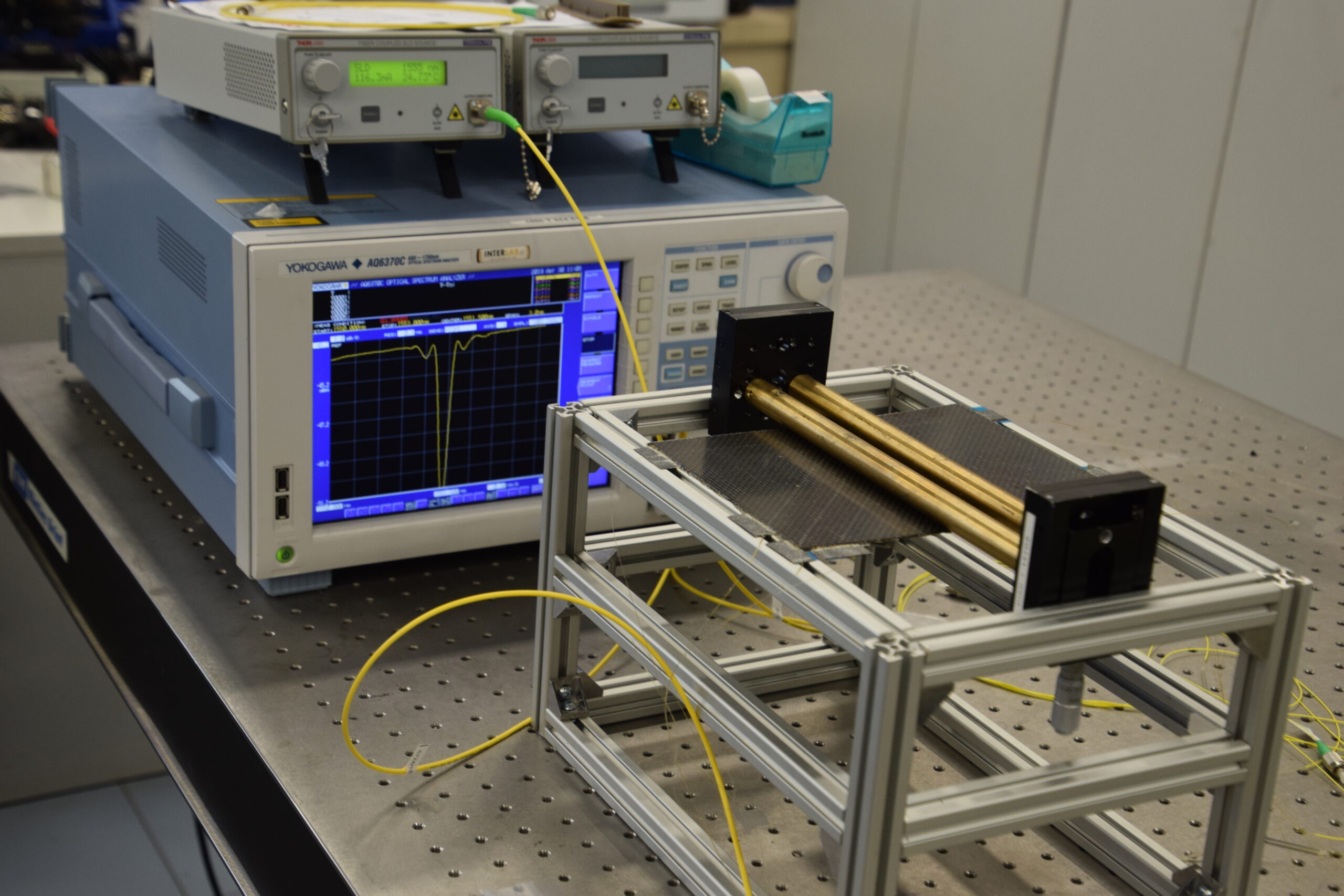

Measurement

Test and measurement equipment for refractive index profiling of preforms and fibres, single wavelength and spectral characterization of transmission (e.g. loss) and guidance (e.g. numerical aperture) properties, regular and high resolution optical time domain reflectometry (OTDR), optical Bragg reflectometry (OBR), spectroscopy, fibre photodarkening assessment, glass characterization (Abbe refractometers, dilatometer, heating microscope), image guide MTF (Modulation Transfer Function) measurements, electron microscopes, X-Ray Diffraction and Scattering equipment, Bragg grating interrogators, FROG based ultrashort pulse characterization.

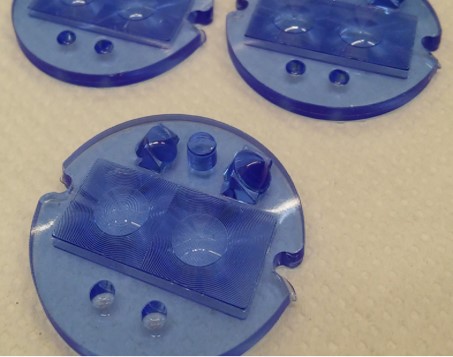

Packaging

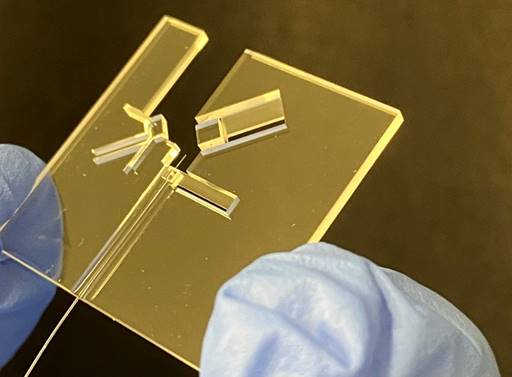

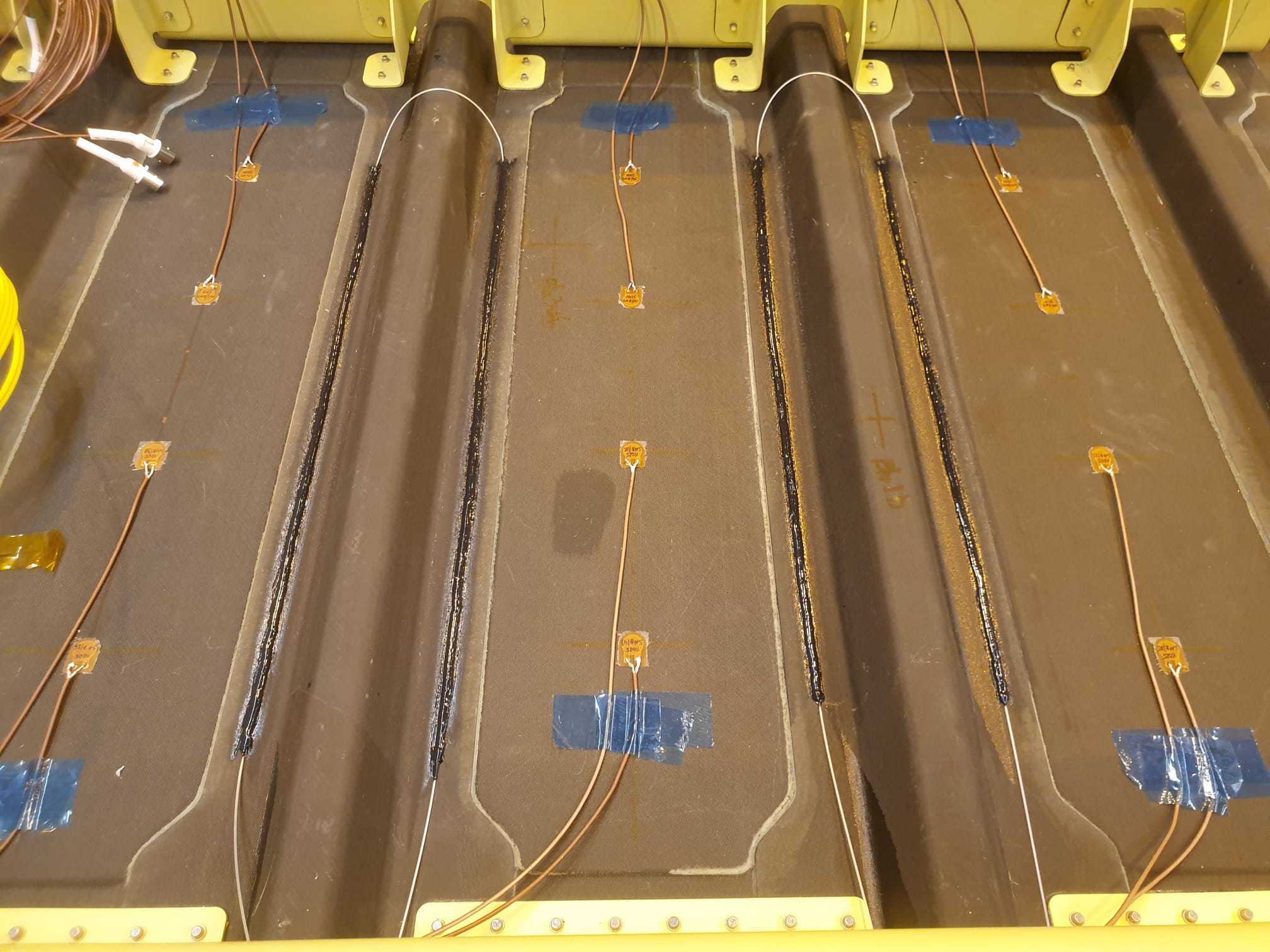

Hosts technologies for fibre end processing and termination including cleaving, splicing, tapering, spherical and elliptical microlens termination, connectorization, cabling. Packaging with micro-extruder, mini-injection moulding machine, mini calendar for film-casting, equipment for RTM, infusion, hot-pressing and hot-embossing processing is provided. Fibre alignment and packaging in diamond-tooled or deep proton written polymer structures, and fibre embedding in both composite and soft polymers, are also made available.

Proof-of-concept

Proof-of-concepts include specialty fibres with tailored features in terms of environmental resistance and sensitivity to specific measures or in terms of gain and loss profiles. TP2 also delivers fibre-based laser or high optical power delivery systems, packaged fibre-based transducers for sensor systems and tailored fibre-based illumination systems.

Reliability testing

Thermal microanalysis (phase transitions, reactions and material degradation) and thermo-mechanical testing equipment (autoclaves and climate chambers, tension/compression, bending (3- or 4-point), buckling, shock, fatigue, interlaminar shear loading, at temperatures ranging from -70 °C to 1000 °C, and in controlled atmospheres), friction and adhesion studies, creep and cupping tests, hardness analysis (macro- and micro-hardness testing, and nanoindentation) and holographic and elasto-optic tomograhps for refractive index profile assessments. Ovens, thermostatic baths and climatic chambers allowing for accelerated ageing studies and for reliability and lifetime prediction.